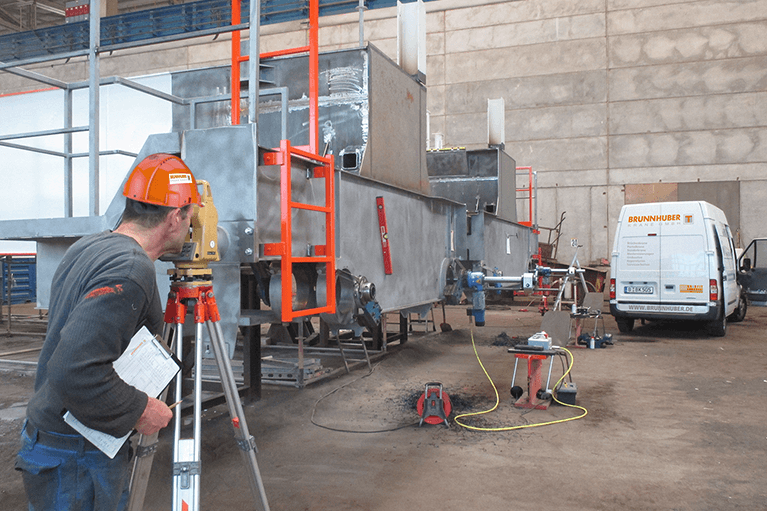

We optimize your crane system with the help of optoelectronic and laser measurements as well as mobile line boring services.

An increased abrasion of rails and flanges does not only cause problems and hinders your processes but also always has a cause. We can detect geometrical false positions with the help of optoelectronic and laser measurements and help you with the solution.

Our qualified service technicians can carry out mobile spindle work up to a diameter of 600 mm at all heights and in the smallest of spaces using the latest precision chipping machines. These measurement serve as a base for individual solutions that we also offer to implement for you.

Technical specifications:

Drills with a diameter from 60-600mm and a bearing clearance of 2400mm can be produced. Any material with a stability of up to 1000N/mm² and a depth of cut of up to 3mm can be measured.